PRODUCT DESCRIPTION

HN-8808, two parts, low viscosity potting compound that cures at room temperature to soft rubber.

1. This potting silicone rubber has high moisture resistance and a wide temperature range of - 57°C to 250°C.

2. Condensed liquid silicone rubber does not use polar compounds as raw materials, and does not release by-products during cross-linking, and can maintain better electrical properties under harsh conditions.

3. Non-toxic, odorless, non-corrosive, non-swelling.

4. It has adhesive force, has adhesion to metal aluminum, iron, acrylic, and PC plastic, and can improve waterproof sealing performance.

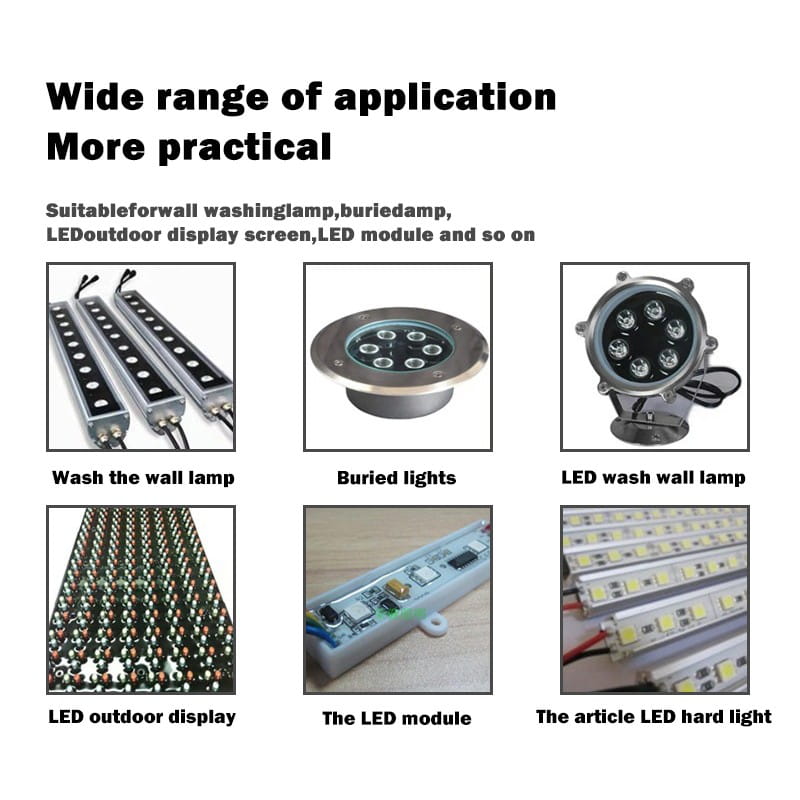

PRODUCT APPLICATION

* Product Application *

Widely used in sealing, electrical, potting, insulation, antifouling, waterproof, shockproof, coating, electronic appliances, and comprehensive household appliances.

TECHNICAL PARAMETERS

* Technical Parameters *

| № |

Itrems |

Technique Request |

| 1 |

Appearance |

Transparent, White, Black

Flowing Liquid

|

| 2 |

Viscosity (before curing) (mPa.S) |

A:2000 B:50 |

| 3 |

Specific Gravity (23℃) |

0.98 |

| 4 |

Available Time (h, 25℃) |

1-2h |

| 5 |

Entirely Cure Time (h, 25℃) |

8-12h |

| 6 |

Shaw Hardness (JIS A) |

25A |

| 7 |

Volume Resistivity (Ω cm) |

≥1×1014 |

| 8 |

Strength of Breakdown Voltage (kv / mm) |

18-25 |

| 9 |

Dielectric Constant (1MHZ) |

2.5 - 3.0 |

| 10 |

Dielectric Loss Angle Tangent (1MHZ) |

≤4×10-3 |

| 11 |

Thermal Conductivity (w / m.k) |

0.1 - 0.20 |

* Noted:

1. Parameters can be adjusted as required.

2. The data in this product description are non-standard values.

3. Test first before using.

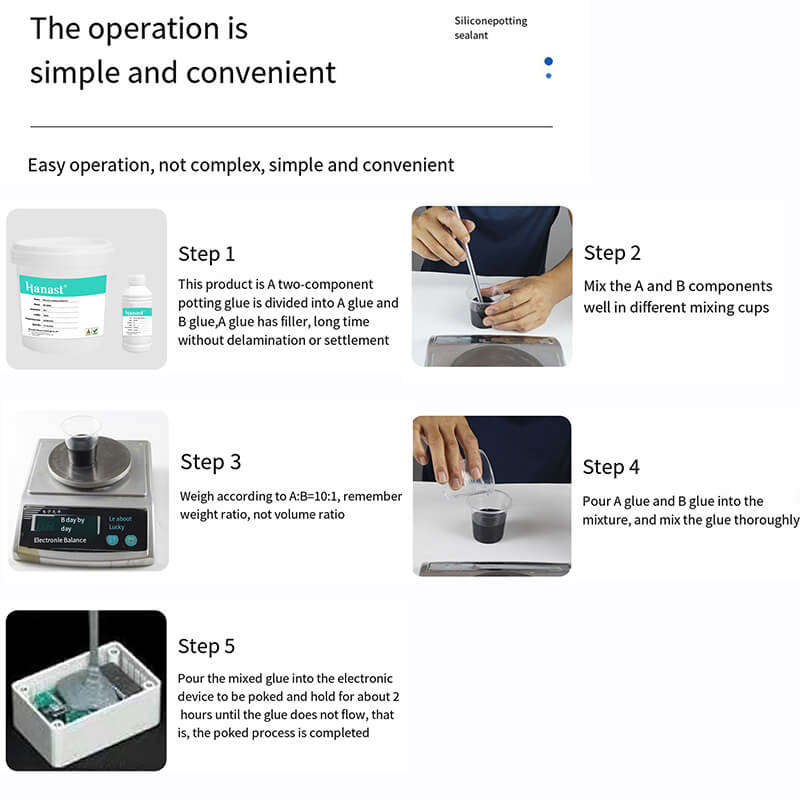

HOW TO USE

* How to use *

According to the dosage, pour it into the mold after mixing according to A: B=10:1.

Remove the surface bubbles and cure at room temperature (the proportion can be adjusted according to actual needs, the larger the proportion of component B, the faster the curing).

PACKING

* Packing *

Part A: 10KG / 20KG Plastic Barrel

Part B: 1KG Plastic Barrel

Home

Home

Related Suggestion

Related Suggestion

Nov 17,2023

Nov 17,2023

Tel

Tel

Email

Email

Address

Address