PRODUCT DESCRIPTION

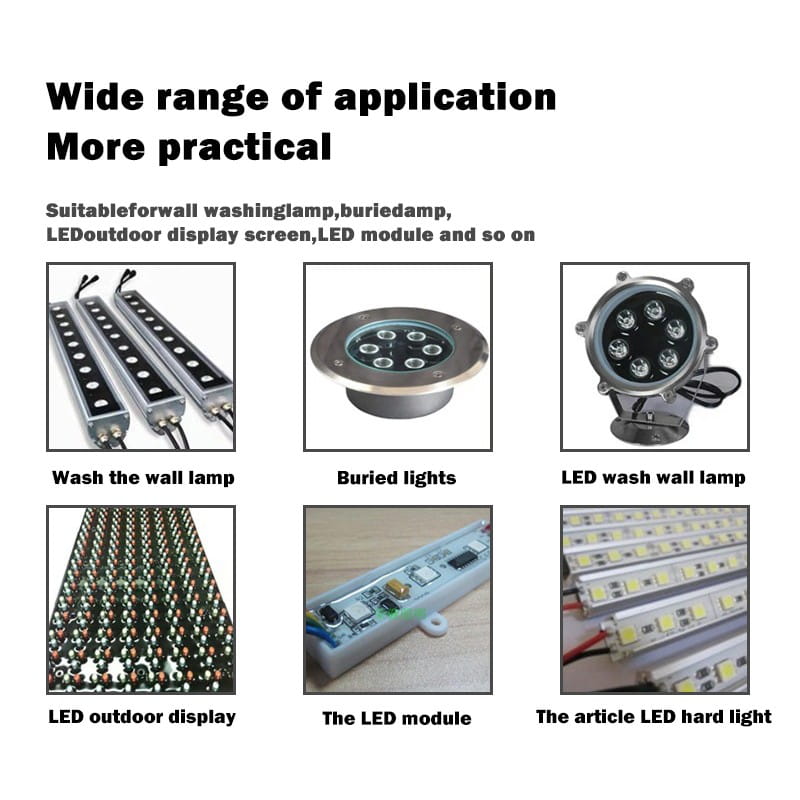

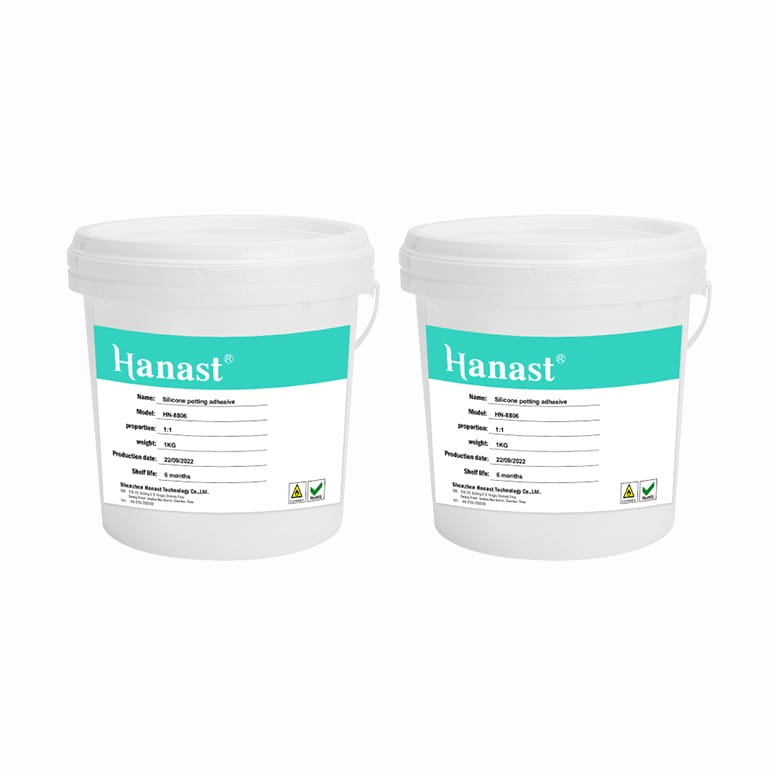

HN-8806, two-component addition type silicone potting rubber which can be cured into high-performance elastomer by room temperature or heating.

This potting silicone rubber has excellent electrical insulation, high moisture resistance, and a wide temperature range of -50°C to 250°C.

Low-viscosity potting compound that Will cure in deep sections. Low shrinkage rate after curing, will not emit heat and by-products, no corrosion for filling and sealing components.

No pollution in the surrounding environment, Complying with RoHs standards.

Its good thermal conductivity function can effectively transfer the heat emitted by the electronic components.

PRODUCT FEATURES

* Product Features *

-

Excellent electrical properties and Thermal conductivity;

-

One hour Fast-curing;

-

Flame retardant, high and low temperature resistance from -50ºC to 250ºC (58°F to 432°F);

-

Aging resistance and moisture-proof;

-

Low shrinkage rate, will not release heat and by-products, no corrosion of potting components after curing;

- Flexible Rubber – Protects components against thermal cycling stress and mechanical shock.

TECHNICAL PARAMETERS

* Technical Parameters *

|

|

Test Items

|

Test Standard

|

Units

|

Product test results

|

|

Part A

|

Part B

|

|

Before

Curing

|

1

|

Appearance

|

By eyes

|

---

|

Grey, fluid

|

White, fluid

|

|

2

|

Viscosity

|

GB/T10247- 2008

|

25ºC,mPa·S

|

4500~5000

|

4500~5000

|

|

3

|

Density

|

GB/T 13354-92

|

25ºC,g/cm3

|

1.50±0.05

|

1.50±0.05

|

|

4

|

Mixing Ratio (A : B)

|

1:1

|

Weight ratio

|

100

|

100

|

|

Volume ratio

|

100

|

100

|

|

5

|

Operating time

|

Measured

|

hr

|

0.3-0.4

|

|

6

|

Curing condition

|

Measured

|

hr

|

4~12

(25ºC, initial cure)

|

|

0.20

(80ºC)

|

|

After

Curing

|

7

|

Appearance

|

By eyes

|

---

|

Grey Elastomer

|

|

8

|

Hardness

|

GB/T 531.1-2008

|

Shore A

|

50±5

|

|

9

|

Thermal conductivity

|

GB/T10297-1998

|

w/m·k

|

≥0.76

|

|

10

|

Expansivity

|

GB/T20673-2006

|

µm/(m,ºC)

|

210

|

|

11

|

Moisture Absorption

|

GB/T 8810-2005

|

24h,25ºC,%

|

0.01~0.02

|

|

12

|

Volume resistivity

|

GB/T 1692-92

|

(DC500V),Ω· cm

|

1.0×1016

|

|

13

|

Dielectric intensity

|

GB/T 1693-2007

|

Kv/mm(25ºC)

|

18~25

|

|

14

|

Temperature Resistance

|

Measured

|

ºC

|

-50~+250

|

* UV-94 Fire retardant: After two times 10s burn tests on a 3mm-thick sample, the flame was extinguished within 30s, and no burnt fell. [1]

* Noted: The data after curing are all measured after the silicone is completely cured.

HOW TO USE

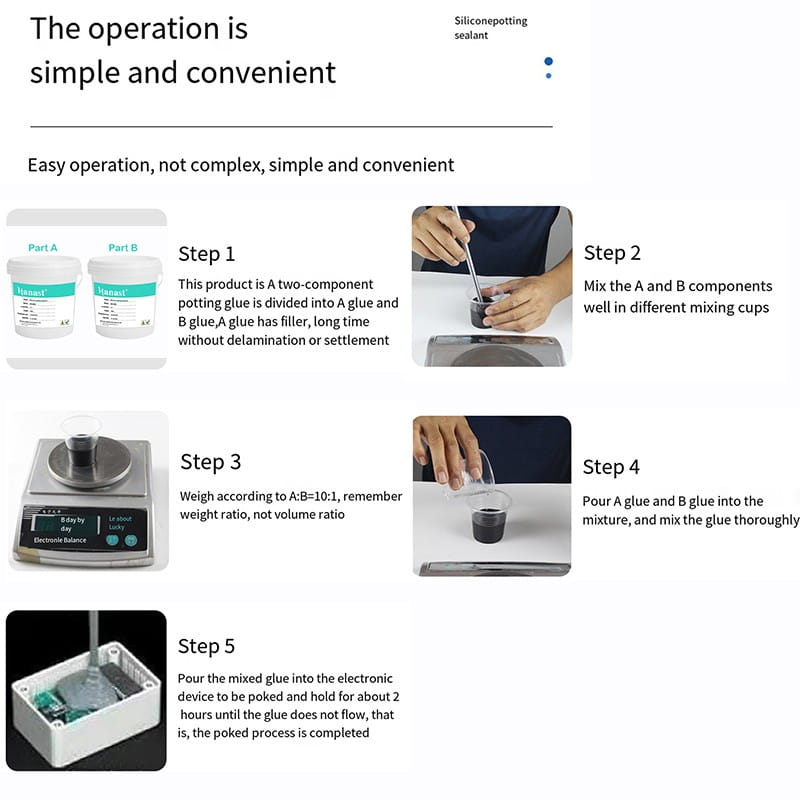

1. When used, weigh A and B according to proportion and then mix them evenly.

Mix thoroughly and evenly with a clean stirring device in a clean container, and then potting can be done.

It can also be sealed under a vacuum after removing the bubbles.

2. The surface of the potting element needs to be cleaned.

If the potting product is too large, it is recommended to potting in stages and then cure at room temperature (4-12hr) or by heating (80ºC-0.5hr).

3. For the automatic potting production line, in order to ensure accurate mixing ratio of A and B, Part A and Part B should be vacuumed respectively to remove the bubbles (the foaming time is 5-10 minutes), and then A and B should be pumped to the static mixer in proportion with a metering pump, and then potting can be done after mixing evenly.

PACKING

* Packing *

10KG / Set (A, 5kg + B, 5kg)

20KG / Set (A, 10kg + B, 10kg)

50KG / Set (A, 25kg + B, 25kg)

- Storage and transportation:

This product is non-toxic non-dangerous goods, according to the general chemical handling, stored in a cool & dry place (room temperature).

- Shelf Life: 6 months, overdue please reinspect; If it meets the standard, it can still be used.

Home

Home

Related Suggestion

Related Suggestion

Nov 17,2023

Nov 17,2023

Tel

Tel

Email

Email

Address

Address