Demolding Techniques for DIY Candle Mold Silicone Mold

Candle mold silicone belongs to a type of liquid silicone rubber, which can replicate the fine patterns of candles and is easy to demould after molding. Suitable for making various holiday candles, DIY candles, candle crafts, and other molds. How to demou

Jun 09,2023

Jun 09,2023

What is the appropriate hardness and strength of mold silicone?

The hardness of mold silicone refers to the ability of silicone rubber material to resist hard material pressing into the surface, which is the hardness of silicone rubber. The hardness range of silicone rubber is from 10 to 80, which allows designers to

Jun 09,2023

Jun 09,2023

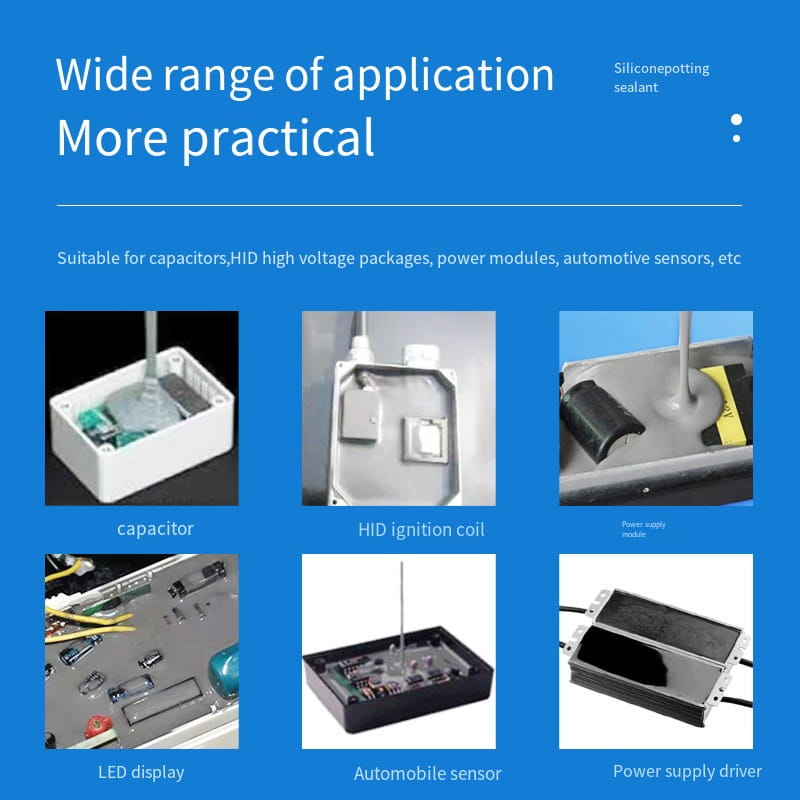

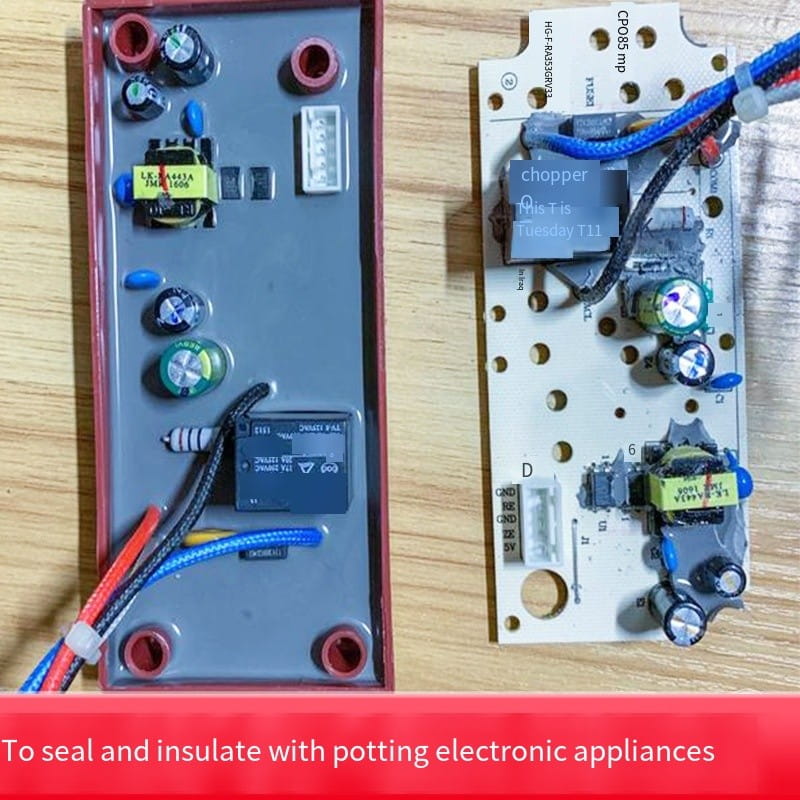

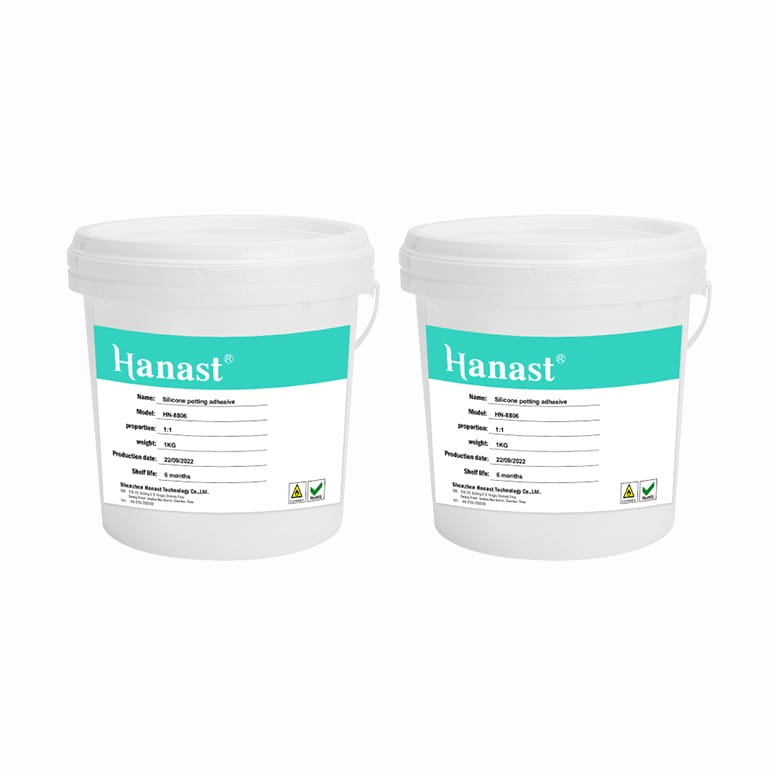

What is the use of electronic glue?

Electronic glue is a broad term, mainly used for bonding, sealing, potting and coating protection of electronic components

May 23,2023

May 23,2023

What is electronic glue?

The main representatives of electronic glue are silicone sealant and silicone potting glue.

May 23,2023

May 23,2023

Precautions after applying thermal conductive silicone grease?

Thermally conductive silicone grease will never solidify after being applied. It should be noted that if the thermally conductive silicone grease is cured, this thermally conductive silicone grease is unqualified and cannot be used in industrial manufacturing in large quantities. You need to pay attention when buying. In order to avoid this situation, users can buy products with word-of-mouth guarantees (such as the series products of Huaneng Zhiyan).

May 22,2023

May 22,2023

The function and operation method of thermal conductive silicone grease

Thermally conductive silicone grease is a common material for electronic heat dissipation performance. It is used for heat conduction and heat dissipation of electronic components such as power amplifiers, transistors, electron tubes, and CPUs, so as to ensure the stability of electrical performance of electronic instruments and meters, and no performance changes before and after use. , always in a grease state.

May 22,2023

May 22,2023

The difference between thermal gel and thermal grease

There are many differences between thermally conductive gel and thermally conductive silicone grease, such as thermal resistance, density, resistivity, etc. Various data show that thermally conductive gel is different from thermally conductive silicone grease, and both have their own advantages. Customers can choose according to their own product characteristics and products Structural requirements, choose to use thermal gel or thermal grease.

May 22,2023

May 22,2023

How should one use thermal grease properly?

First of all, when people use thermal conductive silicone grease, they need to clean up the impurities in the coating layer first, so that the coating layer has a clean and tidy surface, so as to ensure that the thermal conductive silicone grease can have a good performance in the next coating process. environment.

May 22,2023

May 22,2023

What is thermal grease? How should one use thermal grease properly?

Thermal grease has another name, called thermal paste. This heat dissipation paste is made of organic silicone and some other materials with good heat resistance and thermal conductivity into a paste-like substance. Because the materials used in it have good heat dissipation, this silicone material is made It is used in some electronic environments that require heat dissipation, such as: computers, transistors, electronic tubes, etc., thereby ensuring the stability of the performance of electronic components to a certain extent.

May 22,2023

May 22,2023

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address