How to solve the stability of room temperature storage of addition molded silicone rubber

Basic components of addition molded silicone rubber: vinyl silicone oil, reinforcing filler, hydrogen containing silicone oil, crosslinking agent, catalyst. When these components are mixed together, cross-linking reactions occur. Even with the addition of

Jul 03,2023

Jul 03,2023

Doing so will greatly extend the service life of silicone for condensation molds

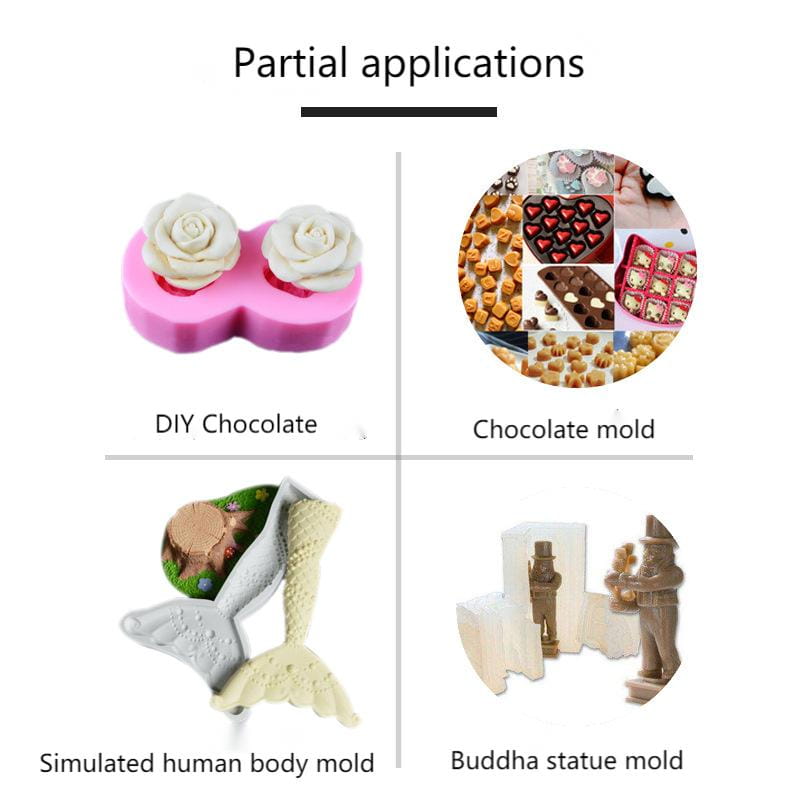

The mold made of condensed silicone mold has the characteristics of convenient flipping and good replication effect, so it is widely used for flipping and replication in industrial buildings, gradually replacing traditional hard molds. Compared to traditi

Jul 03,2023

Jul 03,2023

How to make mold silicone more durable

Mold silicone is a specialized adhesive for making silicone molds. Extending the service life of silicone molds and increasing the number of mold turns not only saves costs but also greatly improves production efficiency, which is also the most desired ef

Jul 03,2023

Jul 03,2023

Reasons and solutions for non curing of liquid silicone

Recently, someone complained to Xiao Bian that the mold silica gel was not fully cured after 48 hours when using liquid silicone for mold reproduction, and the phenomenon of partial non curing occurred.clear liquid silicone for molds For this problem, Xia

Jul 03,2023

Jul 03,2023

Why does mold silicone appear to be dry on the surface and not dry on the inside

As is well known, mold silicone belongs to condensed silicone, which is equivalent to an adsorbent that solidifies by absorbing water from the air. During the production process of silicone, if the water is evaporated to dryness without adding an appropri

Jul 03,2023

Jul 03,2023

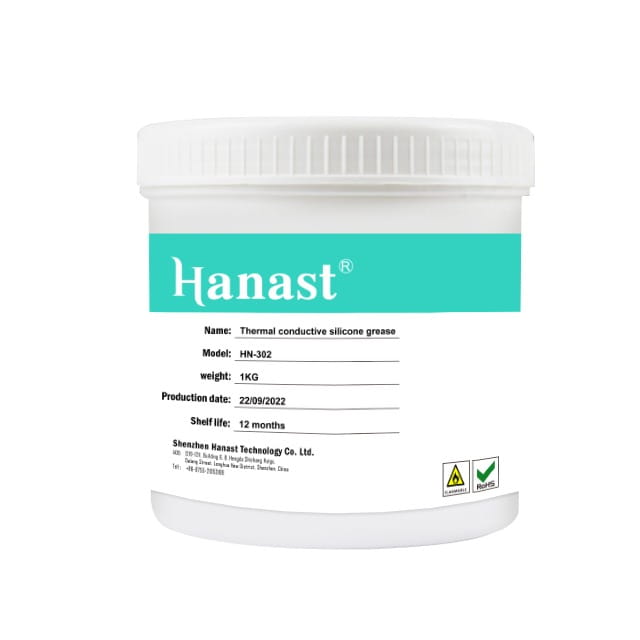

Do you understand the function and performance parameters of thermal conductive silicone grease?

Thermal conductive silicone grease Commonly known as heat dissipation paste, also known as Thermal paste, thermal conductive silicone grease is a thermal conductive organic silicone grease like compound made from organic silicone as the main raw material

Jun 09,2023

Jun 09,2023

Is thermal conductive silicone grease really useful? How to choose thermal conductive silicone grease?

In many industries, thermal conductive silicone grease is often seen. This adhesive has great practical value and its range of use is becoming wider and wider.

What is thermal conductive silicone grease?

Its main material is organic silicone, which has

Jun 09,2023

Jun 09,2023

Introduction to product knowledge of thermal conductive silicone grease

Thermal conductive silicone grease, also known as heat dissipation paste, is a paste made by using special silicone oil as the base oil, adding materials with excellent heat resistance and thermal conductivity, such as new metal oxides as fillers, and add

Jun 09,2023

Jun 09,2023

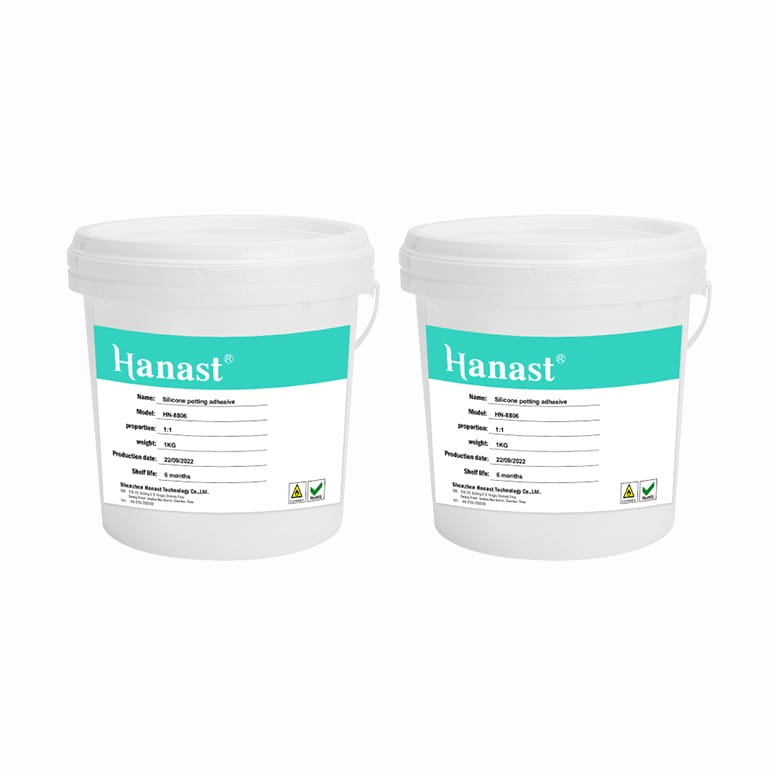

The importance of potting AB glue in electronic product packaging applications

1. Potting AB glue can not only strengthen the integrity of electronic equipment, but also enhance the resistance of electronic equipment to external shock and vibration.

2. Potting AB glue can also improve the insulation between internal components and lines, and is also beneficial to the miniaturization and weight reduction of devices.

3. Potting AB glue can also prevent direct exposure of components and circuits, and can also improve the waterproof and moisture-proof performance of electronic equipment.

4. After the potting AB glue is fully cured, it can also play the role of dust prevention, heat conduction, confidentiality, corrosion resistance and temperature resistance.

Jun 02,2023

Jun 02,2023

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address